09:23 Keyword Reactor 1.0 cracked | |

DETERMINISTIC EVALUATION OF DELAYED HYDRIDE CRACKING BEHAVIORS IN PHWR PRESSURE TUBES YOUNG-JIN OH a YOON-SUK CHANG b,. a Power Engineering Research Institute, KEPCO Engineering and DETERMINISTIC EVALUATION OF DELAYED HYDRIDE CRACKING BEHAVIORS IN PHWR PRESSURE TUBES

Received 16 April 2012. Accepted 31 October 2012. Available online 2 April 2015.

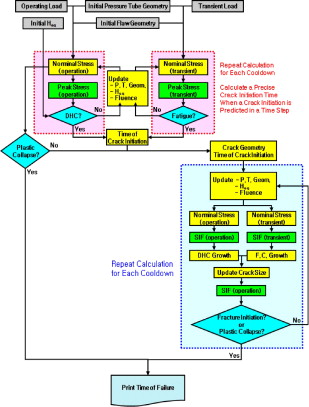

1 INTRODUCTIONA few hundred zirconium alloy pressure tubes in a pressurized heavy water reactor (PHWR) serve as the nuclear fuel channel as well as the reactor coolant pressure boundary. For safe operation of the PHWR, reliable performance of the tubes should be maintained throughout its harsh life environment. However, due to high temperature, pressure and neutron flux, Zirconium alloy pressure tubes may be subjected to aging mechanisms such as ‘delayed hydride cracking (DHC)', ‘irradiation enhanced deformation' and ‘changes of material properties'. To date, some pressure tubes in early reactors have leaked and two pressure tubes have ruptured due to the DHC[1 ]. 2 DETERMINISTIC FLAW ASSESSMENT PROGRAM2.1 Assessment Program SummaryA deterministic flaw assessment program for pressure tubes was developed based on the procedure of CSA N285.8. It aims to predict crack initiation and growth by the DHC as well as final failure by fracture initiation and plastic collapse. Also, the program can provide the times for each event (crack initiation and final failure etc.) and consider the location of a flaw (channel location and axial position of the flaw in the pressure tube). The principal considerations for developing the assessment program are summarized in the following paragraph, which abide by the procedures prescribed in CSA N285.8. Initial volumetric (blunt) flaws in the pressure tubes undergo normal operation and transient loads, which may lead to either fatigue crack and DHC initiation or plastic collapse during operation. Also, hydrogen concentration and neutron fluence increase continuously and nominal stresses increase due to dimensional change of the flawed tubes such as thickness reduction and diametral expansion. So, effects of the hydrogen concentration and neutron fluence increment as well as dimensional change in accordance with time elapse is taken into account for crack initiation evaluation. During these evaluations, the three aforementioned parameters are continuously revised and reevaluated at each time interval to justify the fracture initiation and plastic collapse. Fig. 1 shows a brief flow diagram for the assessment program developed in this study.

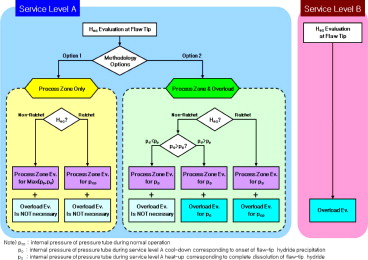

Fig. 1. Flow Diagram of Deterministic Flaw Assessment for PHWR Pressure Tubes CSA N285.8 specifies evaluation options on the DHC initiation in terms of hydrogen concentration. Because pressure tube material contain deuterium as well as hydro-gen in PHWR condition, the hydrogen equivalent concen-tration (Heq ) is defined as follows where, Hi is the initial hydrogen concentration and D is the deuterium uptake. CSA N285.8 describes various options for DHC initiation assessment methods and their scope of application. In this study, the options are briefly depicted in Fig. 2. The DHC initiation assessment methods are classified into two groups; (1) a process-zone evaluation procedure appropriate for pressure tubes with a constant temperature (normal operation) condition or a temperature decrease (cooldown operation) condition, and (2) a hydrided region overload evaluation procedure appropriate for pressure tubes with a temperature increase (upset or heatup transients) condition which has not been documented in CSA N285.8. While the former includes a few kinds of calculation options, such as a threshold peak stress evaluation method and several explicit process-zone methods, all the calculation options are based on the same theory and provide almost identical results for the DHC initiation. So, with regard to the DHC initiation, the threshold peak stress evaluation method with the shortest calculation time was adopted in the flaw assessment program through this research.

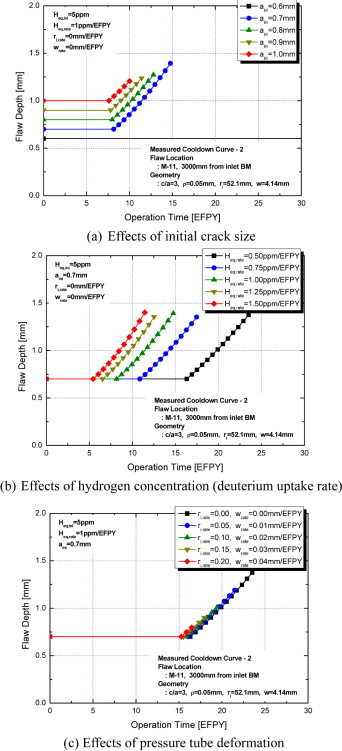

Fig. 2. Flow Diagram of DHC Initiation Evaluation According to CSA N285.8 2.2 DHC Initiation AssessmentDuring the cooldown transient of a PHWR plant, internal pressure and temperature are slowly decreased. Hydrogen is dissolved at the matrix of pressure tube material under high temperature conditions and is precipitated under low temperature conditions. The aforementioned threshold peak stress evaluation method considers that DHC initiation occurs when a maximum applied peak stress under hydride precipitation condition is higher than a threshold value. CSA N285.8 presents a hydride precipitation temperature as follows where, Tp . VH . σhyd1 . σhyd2 . Qp . R. Cp and Hf are the hydride precipitation temperature, partial molar volume of hydrogen in zirconium, hydrostatic stress remote from the flaw tip, hydrostatic stress at the flaw tip, activation energy for hydrogen precipitation, gas constant, hydrogen precipitation constant and bulk hydrogen equivalent concentration in solution remote from the flaw, respectively. The above equation represents that the higher hydrostatic stress gradient, the higher local concentration of hydrogen at the flaw tip which in turns lowers hydride precipitation temperature at the flaw tip. Here, the σhyd1 and σhyd2 are calculated by where, σh is the nominal hoop stress, σa is the nominal axial stress, σp is the peak principal flaw-tip stress and ν is the Poisson's ratio. Because Tp is a function of σh . maximum peak stress under hydride precipitation condition has to be calculated iteratively for many small time steps of cooldown transient scenario. 2.3 DHC Growth AssessmentCSA N285.8 considers that DHC growth occurs when the applied stress intensity factor is greater than a threshold value (KIH ) and temperature is lower than a specific value (T c DHC ). The KIH and T c DHC are presented in CSA N285.8 as follows where, TIH . T c DHC . ΔT c DHC . QD and CD are the threshold stress intensity factors for the onset of DHC from a crack, maximum temperature for DHC growth during continuous cooling, undercooling for T c DHC during continuous cooling, activation energy for hydrogen dissolution and hydrogen dissolution constant, respectively. Under the DHC growth condition, flaw growth rate varies according to temperature conditions and is not influenced by applied stress intensity factors. A strong correlation was observed between increased temperatures and the flaw growth rate. 2.4 Reliability of Flaw Assessment Program3 EFFECTS OF FLAW SIZE AND HYDROGEN CONCENTRATIONThe DHC behaviors of volumetric flaws were estimated by using the program to investigate the effects of varying input parameters. Even though fatigue remains a more plausible crack initiation mechanism than delayed hydride cracking, in general, evaluation of the fatigue crack initiation was excluded by considering inherent over-conservatism of the relevant procedure in CSA N285.8-05[6 ] and prime object dealing with the DHC assessment of the present study. A postulated volumetric flaw at the center of a high power fuel channel, which is 3,000mm away from the inlet burnish mark of a pressure tube, was chosen for the evaluation under a representative cooldown transient. Fig. 3 shows the resulting flaw behaviors, in which the crack initiation and growth from the volumetric flaw are dependent on the initial flaw size, Heq and pressure tube dimensional change. Here, constant flaw depths mean that the DHC initiation does not occur from the volumetric flaw. However, as the elapse of operation time, the flaw depth increases due to crack initiation and growth to culminate in failure conditions of the pressure tubes by the fracture initiation or plastic collapse.

Fig. 3. Flaw Behaviors at Operating PHWR Pressure Tubes 4 EFFECTS OF COOLDOWN TRANSIENTS4.1 Simplified Cooldown Transients

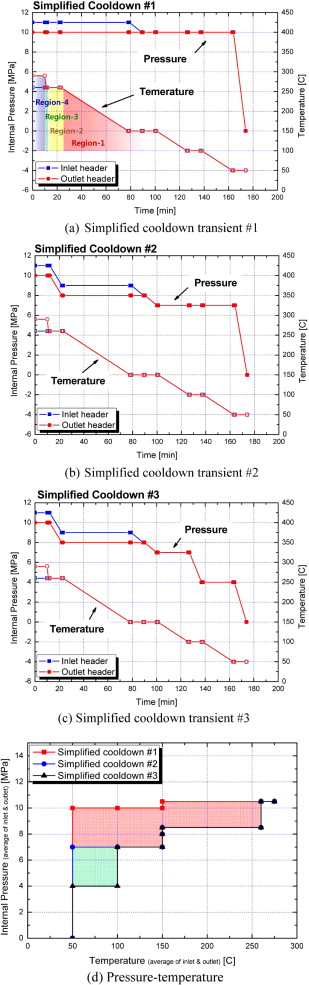

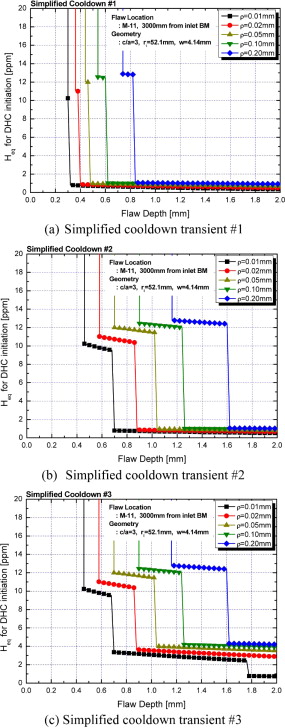

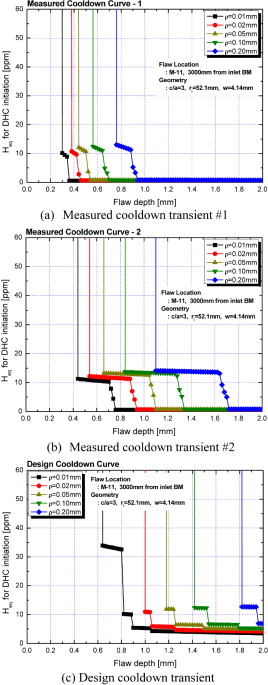

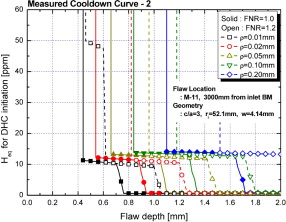

Fig. 4. Simplified Hypothetical Cooldown Transients 4.2 DHC Initiation under Simplified Cooldown TransientsFig. 5 represents variation of the threshold bulk Heq for the DHC initiation against flaw depths (a ) and radii at the tip of a blunt volumetric flaw (ρ) under the simplified cooldown transients. As shown in the figure, at a given flaw depth, the threshold bulk Heq increases as the increase of ρ. It can be explained that higher bulk Heq is needed for the DHC initiation because stress gradients and local Heq at the flaw-tip decrease as the increase of ρ. However, the DHC can be initiated as a result of an increase in the flaw depth because a deeper flaw contributes to a larger stress gradient and higher local Heq at the flaw tip. Meanwhile, we can find out the effects of the change of simplified cooldown transients; for instance, in the case of cooldown transient %233 with three steps of depressurization, further higher threshold bulk Heq is anticipated for the DHC initiation although the flaw depth is deep and ρ is small.

Fig. 5. Threshold Bulk Heq for DHC Initiation under Simplified Cooldown Transients

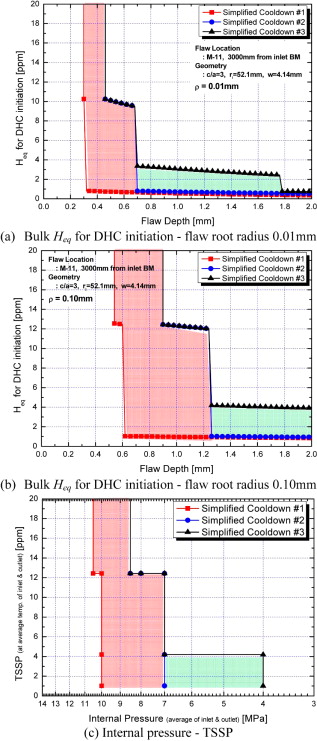

Fig. 6. Understanding the Effect of Cooldown Transient on DHC Initiation

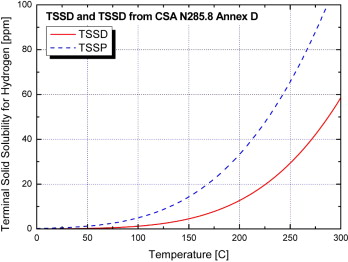

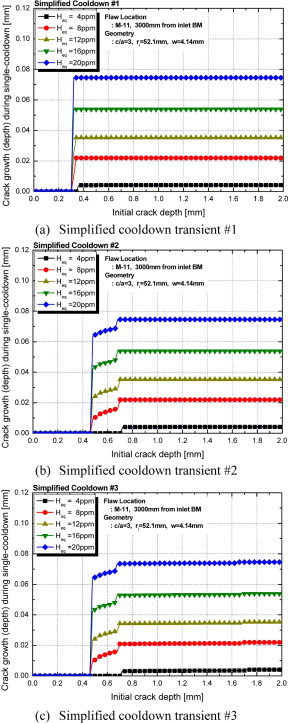

Fig. 7. TSSD and TSSP of Pressure Tube Material The evaluation results can be interpreted that, at a certain bulk Heq . possibility of the DHC initiation reduces under the cooldown transient condition with early depressurization because of the increase of threshold flaw size for the DHC initiation. Using the similarities of Fig. 6(a)∼Fig. 6(c). we can estimate the most effective depressurization procedure under a cooldown operation to minimize the DHC initiation possibility considering average Heq level of a given reactor. 4.3 DHC Growth under Simplified Cooldown TransientsFig. 8 represents variation of the DHC growth rates against the initial crack depth with different Heq . As shown in the figure, although the initial crack depth does not significantly affect the crack growth rate, early depressurizations under cooldown transients %232 and %233 lead to deeper threshold crack depths for the DHC growth. The increase of the bulk Heq decreases T c DHC that widens temperature ranges and results in the increase of flaw growth under a cooldown operation. In contrast, for the deeper initial crack depth over 0.8mm approximately, DHC growth rates are not affected by the initial crack depth and cooldown transient. While the deeper crack causes larger applied stress intensity factor than KIH but the DHC growth rate does not depend on the applied stress intensity factor as described in Section 2.3. Due to little difference in time-temperature curves among cooldown transients as shown in Fig 4(a)∼Fig. 4(c). there is no difference in the amount of DHC growth for the deeper crack.

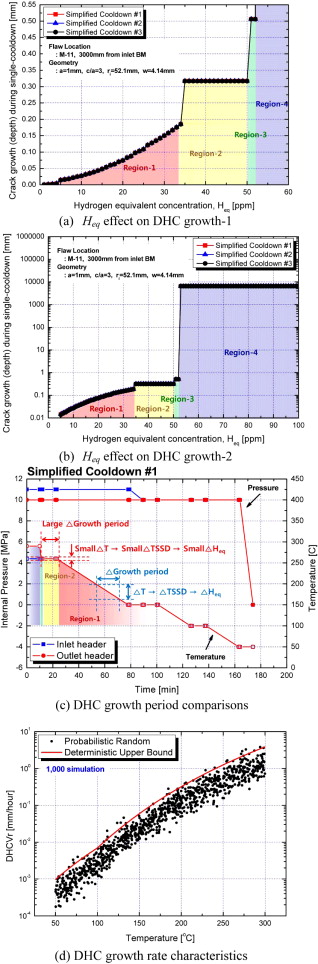

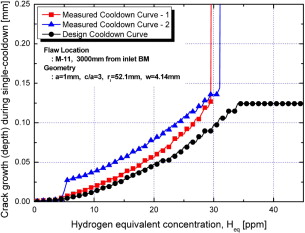

Fig. 8. Effect of Crack Size and Heq on DHC Growth under Simplified Cooldown Transients Fig. 9 represents variation of the DHC growth during single cooldown operation against bulk Heq when the initial crack is sufficiently deep as aini .=1.0mm. As shown in the figure, there was no effect of cooldown transient on DHC growth if the initial crack is sufficiently deep. The Region-1 in Fig. 4(a) representing later half of the cooldown operation can also be used to explain characteristics of the Region-1 in Fig. 9(a) and 9(b). in which the amount of DHC growth increases gradually according to the increasing bulk Heq at low level of Heq . This means that increasing bulk Heq increases the DHC growth period during later half of the cooldown operation as shown in Fig. 9(c) .

Fig. 9. Understanding the Effect of Heq on DHC Growth under Normal Operation and Cooldown Transients Especially, the amount of crack growth abruptly increases when the bulk Heq is about 35ppm and the region with constant crack growth rate is followed by the Region-2 in Fig. 9(a) and 9(b). When the Heq increases from 33ppm to 35ppm, the terminal solid solubility for dissolution (TSSD) temperature increases from 258°C to 260°C (refer to Fig. 7 ). The small increment of TSSD temperature induces large increment of the DHC growth period, about 15 minutes in Region-2, which phenomenon is graphically illustrated in Fig. 9(c) . A similar trend is observed in the region with the Heq of 50ppm, which corresponds to the Region-3 in Fig. 4(a). Subsequently, significant crack growth occurs in the Region-4 since this region is pertinent to sustained normal operation conditions at high temperatures. Fig. 9(d) represents that the DHC growth rate of pressure tube material is rapidly increased at higher temperature as described in CSA N285.8. Therefore, during early part of cooldown operation (high temperature part), relatively small increment of DHC growth period may lead to large amount of increment of DHC growth by single cooldown operation. 4.4 DHC Behaviors under Plant Cooldown Transients

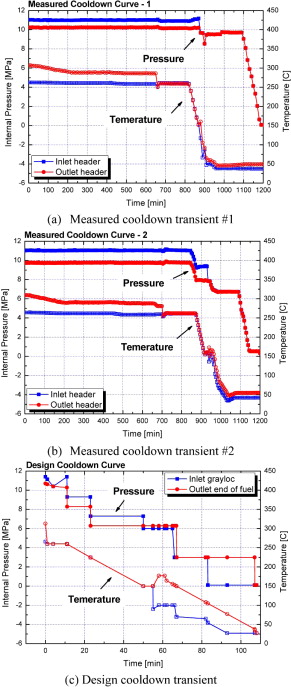

Fig. 10. Cooldown Transients for Korean PHWR Plants

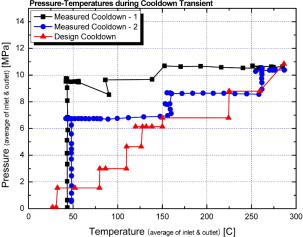

Fig. 11. Pressure-Temperature Curve for Plant Cooldown Transients

Fig. 12. Threshold Bulk Heq for DHC Initiation under Plant Cooldown Transients

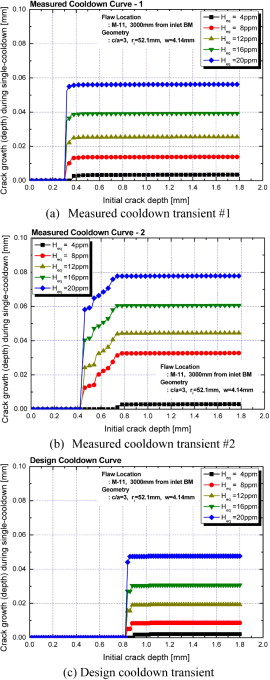

Fig. 13. Effect of Factor of Non-ratchet on DHC Initiation under the Measured Cooldown Transient %231 Fig. 14 shows characteristics of the DHC growth by single cooldown operation. In this figure, depressurized transients increase the threshold crack depth for DHC growth. However, when the initial crack is deeper than 0.9mm, early depressurization effects are disappeared. In case of the measured cooldown transient %232 with two-step depressurization, the crack growth rate is greater than that of the measured cooldown transient %231 as shown in Fig. 15. This DHC growth behavior can be interpreted as the increased crack growth period effect according to the decrease of average cooldown rate, i.e. the increased period at high temperature during a cooldown, instead of the depressurization effect. It is also supported by the evaluation results depicted in Fig. 9. in which the pressure reduction effect is not observed under the simplified hypothetical cooldown transients having the same cooldown rate. Therefore, it can be summarized that the early depressurization can contribute to the increase of the threshold initial crack size for the DHC growth under the cooldown transient and rapid cooling from high temperature is effective to reduce the amount of DHC growth during a cooldown operation.

Fig. 14. Effect of Crack Size and Heq on DHC Growth under Plant Cooldown Transients

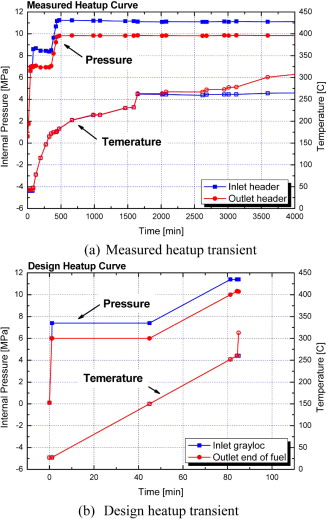

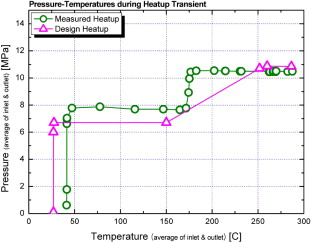

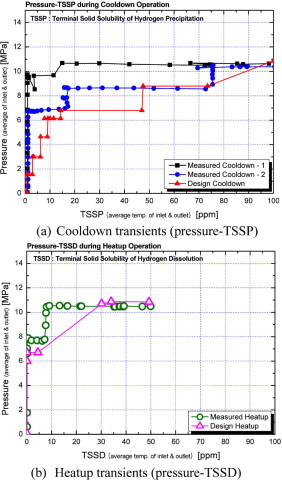

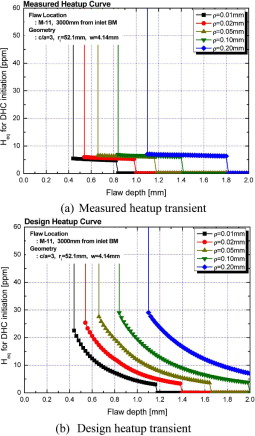

Fig. 15. Effect of Heq on DHC Growth under Plant Cooldown Transients 5 EFFECTS OF HEATUP OPERATION SCENARIOWhile the DHC growth has been evaluated under the normal and cooldown operating conditions, in case of the DHC initiation, heatup operation should also be considered. As illustrated in Fig. 2. the DHC initiation under the heatup operation can be evaluated by using the process-zone evaluation procedure or the hydrided region overload evaluation procedure. However, since details of the latter procedure are not established yet but the former procedure is available from CSA N285.8, characteristics related to the DHC initiation were examined in this section based on the process-zone evaluation procedure. Fig. 16 represents two kinds of heatup transients; the one in Fig. 16(a) is measured from a Korean PHWR plant[10 ] and the other in Fig. 16(b) is extracted from a design stress report of the same plant[11 ]. These plant heatup transients were translated into the corresponding pressure-temperature curves as shown in Fig. 17. Here, the pressure in the design stress report is lower than the measured one for a given temperature.

Fig. 16. Plant Heatup Transients

Fig. 17. Pressure-Temperature Characteristics of Plant Heatup Transients

Fig. 19. Threshold Bulk Heq for DHC Initiation under Plant Heatup Transients 6 DISCUSSION ON COOLDOWN OPERATION PROCEDUREDepressurization during cooldown operation can contribute to reducing DHC risks but it must not cause diminishment of the reactor stability. For example, the depressurization under lower temperature than 100°C is not effective to reduce the DHC risk. Depressurization with a temperature higher than 150°C is more effective to reduce the DHC risk, especially for the pressure tubes which have higher Heq . Figs. 5(a) and 7 can be used for determining most effective depressurization temperature taking into account plant specific Heq . Rapid cooling from high temperature is effective to reduce the amount of DHC growth during a cooldown operation. The cooling rate must not be higher than the limit value from original design specification or operating procedure of the plant. In addition, a probabilistic assessment program for pressure tube flaw integrity is being developed based on the present study. It is expected that, in the near future, effective cooldown procedures can be deduced from probabilistic assessment techniques and plant specific quantitative analyses for reduced DHC risks depending on cooldown operating scenarios. 7 CONCLUSIONSIn this research, a deterministic DHC evaluation program was developed based on CSA N285.8 procedure prior to expanded probabilistic damage frequency assessment. It was used for systematic structural integrity assessment of the pressure tubes with a volumetric flaw, from which the following conclusions were made. The DHC initiation time of volumetric flaws is mainly dependent on the flaw size, radius at the flaw-tip, initial hydrogen equivalent concentration, deuterium uptake rate (Heq rate), cooldown and heatup operation scenarios. The effect of the pressure tube deformation was relatively insignificant. The DHC can be initiated earlier for sharper flaw, deeper flaw and higher Heq . The DHC initiation can be roughly estimated by using the pressure-TSSP curve translated from the cooldown operation curve. The DHC initiation and subsequent growth can be mitigated through a cooldown operation with depressurization at higher temperature. However, this beneficial effect disappeared when the initial crack was large enough to cause the crack growth. Application of the process-zone evaluation procedure led to overly conservative results during the heatup process. ACKNOWLEDGMENTSThe authors wish to thank Dr. Han-Sub Chung and Dr. Seong-Nam Choi of KHNP central research institute and Dr. Young-Suk Kim of Korea atomic energy research institute for their valuable discussions. REFERENCESCopyright © 2013 Korean Nuclear Society. Published by Elsevier B.V. Citing articles ( )Keyword Reactor 1.0 cracked Free DownloadKeyword Reactor 1.0 cracked FREE DOWNLOAD | |

|

| |